Cable Tie "Type" Classifications - Including Type 21S

Cable Tie “Type” Classifications

All cable ties are not created equal!!! With an increasing number of global sources for cable ties and their accessories, and the seemingly limitless uses for them, NEMA supports a global approach to the selection and specification of cable ties for electrical installations. That’s why NEMA members invested directly in the development of international standard IEC 62275, Cable ties for electrical installations, and that’s why they have supported its adoption throughout North America.

IEC 62275, Edition 2 was published in 2013. North American harmonized standard UL 62275 (U.S.) / CSA C22.2 No. 62275 (Canada) /NMX-J-623-ANCE (Mexico), Cable ties for electrical installations, was published February 26, 2010* .

Products conforming to this new standard will be identified by new “Type” classifications and standard performance ratings declared by the manufacturer and confirmed by the tests in the standard. When the official mark of a third-party certification organization is shown in association with a Type Classification and declared Performance Ratings that mark attests (certifies) to the manufacturer’s declarations.

Like most fasteners, the principal measure of performance for a cable tie is its loop tensile strength. However, unlike many other types of fasteners, cable ties serve a very wide variety of fastening functions in many diverse application environments. Depending on the application of the product, loop tensile strength may not always be the only performance characteristic.

While the Type classification and performance ratings described in the following sections are addressed in standards for “cable ties for electrical installations” these classifications and ratings are applicable to many non-electrical applications for cable ties.

The following text provides details on the new Type classifications and standard performance ratings that will greatly simplify selection and specification of cable ties.

*Cable tie requirements in current binational standard UL 1565 / CSA C22.2 No.18.5, Positioning Devices, were retired in June, 2014.

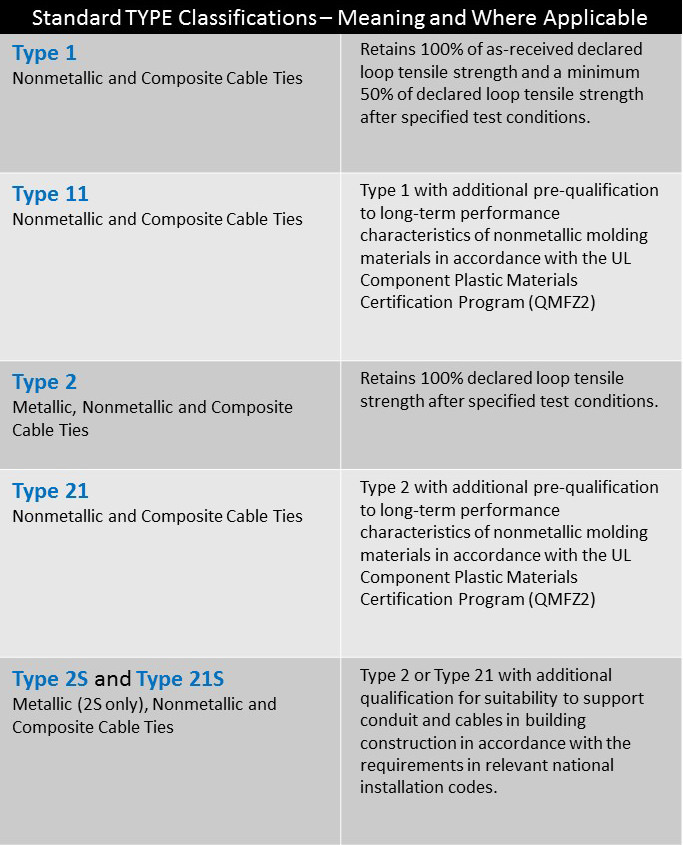

The standard “Type” Classification is based on the demonstrated ability of the product to retain performance characteristics both before and after exposure to various conditions.

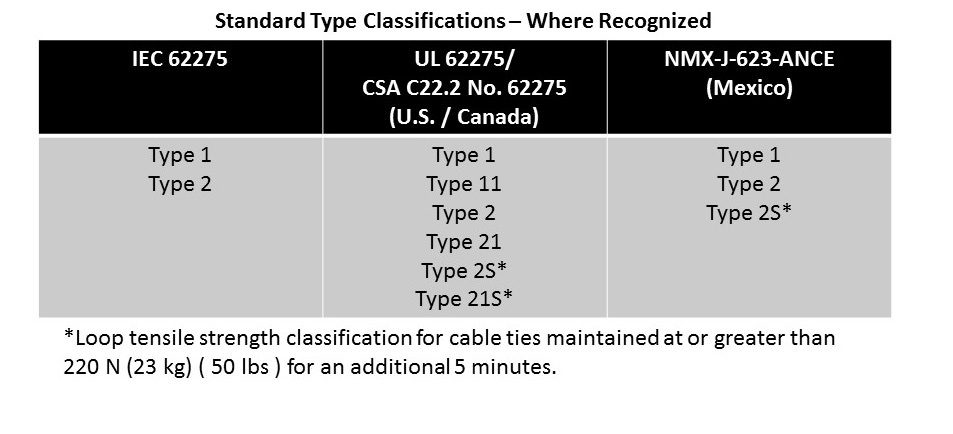

IEC 62275, on which the North American harmonized standard is based, contains the two basic Type Classifications: Type 1 and Type 2.

UL 62275 and CSA C22.2 No. 62275 contain the same two basic Type 1 and Type 2 Classifications. Additionally, Type 11 and Type 21 are introduced in these standards indicating that the product is produced from polymer materials that are subjected to a separate material performance investigation for long-term thermal properties according to ANSI/UL 746B(2) .

Note: IEC 62275 states in an “in some countries” clause that Type 11 and Type 21 are recognized in the US and Canada.

Additional Type classifications Type 2S and Type 21S indicate that cable ties are suitable for securing and supporting conduit and cables in building construction in accordance with the requirements in relevant national electrical installation codes.

More about Type 11 and Type 21 Classifications

There are several benefits to the Type 11 and Type 21 classifications including an increased level of safety in design of the end product, consistency of test data and the availability of material performance data.

Pre-qualified materials used in the manufacture of cable ties adds value in the form of increased dependability over the life of the installation when all appropriate performance ratings for the end use application are taken into consideration. Presently, Mexico does not officially recognize a polymer material certification program. Therefore, Type 11 and Type 21 are not recognized in standard NMX-J-623-ANCE in Mexico.

Standard Performance Ratings

The principal measure of performance for a cable tie is its loop tensile strength. Cable ties serve a wide variety of fastening functions in many diverse application environments. Depending on the application of the product, tensile strength may not always be the only performance characteristic.

Some performance characteristics can be affected by temperature, time, moisture and other environmental conditions. Cable tie standards require individual performance tests to evaluate the effects of these influences.

Declared Performance Ratings

The standards for cable ties define the terms and measure in each performance rating category. Manufacturers have the option to declare the Type Classification of their product, which is confirmed through compliance with the standard.

Terms associated with some of the performance ratings for cable ties may not be fully understood. The following explains these specific performance ratings.

Performance Rating Categories 1. Mechanical 2. Thermal 3. Environmental 4. Fire Effects

Mechanical Performance Ratings

The mechanical performance rating for cable ties is expressed in terms of “minimum loop tensile strength” defined as:

“Minimum Loop Tensile Strength” – a reference mechanical characteristic of a cable tie with its locking mechanism engaged

As addressed in the standard, loop tensile strength does not provide a reliable indication of long-term static load-bearing capabilities. The loop tensile strength test on cable ties exerts the force from the inside out applying stress to the locking mechanism.

The loop tensile strength tests conducted on Type 2 and Type 21 cable ties include a maximum slippage restriction. These cable ties must retain 100% of their declared loop tensile strength after being subjected to specified environmental conditions. Type 1 and Type 11 cable ties must attain 100% of the declared loop tensile strength in the as-received condition, and retain at least 50% of the declared loop tensile strength after being subjected to specified environmental conditions.

Thermal Performance Ratings

The temperature, or range of temperatures to which cable ties may be exposed after installation is an important factor to consider when assessing the right cable tie for a particular application.

The thermal performance ratings declared according to standards UL 62275, CSA C22.2 No. 62275, NMX-J-623-ANCE and IEC 62275 include:

- Maximum Operating Temperature for Application

- Minimum Operating Temperature for Application

- Minimum Temperature for Installation

The maximum operating temperature declared by the manufacturer for cable ties classified as Type 11, Type 21 or Type 21S is not permitted to exceed that of the polymeric material (RTI-Strength) predetermined under independent testing

The declared Maximum Operating Temperature for Application (1) (2) is the maximum continuous temperature at which a cable tie is expected to continuously operate after being installed. This should also be considered the peak operating temperature to which the product should be exposed. The table below indicates the most common declared maximum operating temperatures for cable ties. The manufacturer however has the option of declaring higher ratings.

The declared Minimum Operating Temperature for Application (2) (3) is the minimum continuous temperature at which a cable tie is expected to continuously operate after being installed. This should also be considered the lowest temperature at which the product should be exposed. The table below indicates the most common declared minimum operating temperatures for cable ties. The manufacturer however has the option of declaring lower ratings.

The declared Minimum Installation Temperature (4) is the minimum temperature at which a cable tie can be assembled during installation. This temperature need only be identified if declared below 0° C.

Fire Effects Performance Ratings

In particular, in electrical installations where arcs and sparks might ignite combustible materials, a minimum degree of resistance to flammability for nonmetallic materials is expected. In the North American and IEC standards the requirements fall under “Contribution to Fire”. IEC 62275 contains classification options “Flame Propagating” and “NonFlame Propagating” . The harmonized North American standards require all cable ties to be classified “Non-flame Propagating ” .

Type 1, Type 2 and Type 2S cable ties are required to be needle flame tested according to IEC 60695-11-5.

Type 11,Type 21 and Type 21S are constructed from polymer materials having a flammability rating that has been separately determined by independent testing1 . These require a minimum “HB” rating according to IEC 60695-11-10, UL 94 or CSA C22.2 No. 0.17. Additional ratings V-0, V-1 and V-2 are also acceptable.

Products of all metallic construction are inherently “NonFlame Propagating ” .

Smoke and Heat Effects Type 21 and Type 21S ( A H-2 ) nonmetallic Type 2 and Type 2S ( AH-1 ) metallic

In the United States and Canada, cable ties installed in areas used for the exchange of environmental air ( air-handling spaces or “ p lenums ” ) are required to be classified AH-1 or AH-2. UL 62275 and CSA C22.2 No. 62275 include a Smoke and Heat Release Test which results in a specific minimum index of characteristics. This index is in line with the national mechanical installation codes.

Standard Heat and Smoke Index

- The peak heat release rate shall be ≤ 100 kW

- The peak normalized optical density shall be ≤ 0.5

- The average normalized optical density shall be ≤ 0.5

Environmental Performance Ratings

Particular environmental exposures can have an effect on the performance of cable ties in both the short- and long-term. While it is nearly impossible to address all such influences in a standard, UL 62275, CSA C22.2 No. 62275, NMX-J-623-ANCE and IEC 62275 address the following common environmental conditions:

- Resistance to ultraviolet light

- Resistance to corrosion

Resistance to ultraviolet light(1) is an optional declaration and pertains only to cable ties constructed from nonmetallic or composite materials. Products identified as “UV Resistant” in addition to their Type classification may also be identified “For outdoor use” or “For indoor or outdoor use”. The effects of longterm UV exposure is not exclusive to outdoor installations.

The declaration for Resistance to Corrosion(2) pertains only to metallic cable ties or products constructed of composite materials containing metal. This is an optional declaration in IEC 62275 but is required in the harmonized North American standards.

(1) Aging samples for 1000 hours in a temperature controlled chamber containing a xenon-arc lamp with intermittent water spray.

(2) Exposure to neutral salt spray and elevated temperatures.

After both of these conditionings, tensile testing is conducted according to the declared Type classification.

Notice and Disclaimer

The information in this publication was considered technically sound by the consensus of persons engaged in the development and approval of the document at the time it was developed. Consensus does not necessarily mean that there is unanimous agreement among every person participating in the development of this document.

The national Electrical Manufacturers Association (NEMA) standards and guideline publications, of which the document contained herein is one, are developed through a voluntary consensus standards development process. This process brings together volunteers and/or seeks out the views of persons who have an interest in the topic covered by this publication. While NEMA administers the process and establishes rules to promote fairness in the development of consensus, it does not write the document and it does not independently test, evaluate, or verify the accuracy or completeness of any information or the soundness of any judgments contained in its standards and guideline publications.

NEMA disclaims liability for any personal injury, property, or other damages of any nature whatsoever, whether special, indirect, consequential, or compensatory, directly or indirectly resulting from the publication, use of, application, or reliance on this document. NEMA disclaims and makes no guaranty or warranty, expressed or implied, as to the accuracy or completeness of any information published herein, and disclaims and makes no warranty that the information in this document will fulfill any of your particular purposes or needs, NEMA is not undertaking to render professional or other services for or on behalf of any person or entity, nor is NEMA undertaking to perform any duty owed by any person or entity to someone else. Anyone using this document should rely on his or her own independent judgment or, as appropriate, seek the advice of a competent professional in determining the exercise of reasonable care in any given circumstances. Information and other standards on the topic covered by this publication may be available from other sources, which the user may wish to consult for additional views or information not covered by this publication.

NEMA has no power, nor does it undertake to police or enforce compliance with the contents of this document. NEMA does not certify, test, or inspect products, designs, or installations for safety or health purposes. Any certification or other statement of compliance with any health or safety-related information in this document shall not be attributable to NEMA and is solely the responsibility of the certifier or maker of the statement.

RFQ (

RFQ (